Shipboard Equipment

Home / Products / Shipboard Equipment / Shipboard Equipment Supply / Pipe & Fittings

Pipe & Fittings

Heavy Duty Fittings

High pressure fittings 3000 to 9000lbs.

Bronze – cast, forged steel A105, stainless 304 or 316.

Aluminium 6061/5086, copper nickel, monel.

45º, 90º, tees, crosses, ‘Y’ lateral, union and couplings.

Available in imperial or metric sizes.

CuNi 90/10 and 70/30 to Mil-C-15726, monel CuNi to Mil-QQ-N-288.

Use in US Navy and Royal Australian Navy ships.

CuNi Fittings - Special

Manufactured IAW drawings and material specifications supplied.

DIN (metric), BS (British Standard) or Mil Spec requirement.

Material: 90-10 CuNi, 70/30 CuNi, 316 SS, aluminium and titanium.

Flanges, buttweld fittings, nipples, couplings and sockets etc.

Pressure Ratings: to 6000lbs.

Sizes: 1/8 to 8 inches.

Manufactured in Australia.

Aluminium Pipe & Fittings - Navy

45º and 90º elbows, tees, couplings and unions.

Alloy 356 cast or 6061 extrusions.

Metric or imperial sizes.

Butt weld or socket weld.

Shed 40 or shed 80 – 5086 grade.

Y lateral, crosses, long and short radius or stub ends.

Material certification – chemical and mechanical analysis.

Fibreglass Pipe Systems – Navy - Offshore

Reinforced epoxy pipe products.

Size Range: 1½” to 36” diameter to 225ºF.

Cost saving installation: no hot work, sentries or specialists welders required.

Joining: glued, threaded, spigotted, flanged, butt or o’ring.

Excellent offshore corrosion control in a variety of low to high pressure applications.

Lightweight, fire resistant (IMO level 3) conductive carbon fibre for hazardous area.

Approvals: RAN, USN, USCG, ABS, FDA, ASME and ANSI B31.3.

Ermeto Fittings

Elbows, couplings, crosses, rings, nuts and tees designed to suit metric tube 4mm to 42mm.

Available in 3 pressure ranges – low, medium and high (LL, L & S – Series).

Field assembly, low cost assembly, minimum tooling required on site.

Materials – steel, stainless steel and / or brass.

Low torque – all nuts of EO fittings are coated in a highly effective lubricant.

Temperature Rating – sub zero to high elevated temperatures.

Uses: fuel, lube oil, cooling fresh water, gas turbine, propulsion, bilge vents and hot/cold water.

Compatibility: various fluids and atmospheric conditions are extensive.

Interchangeability: 50 different configurations and 25 sizes.

Re-usability: many times over / visual inspection for serviceability at a glance.

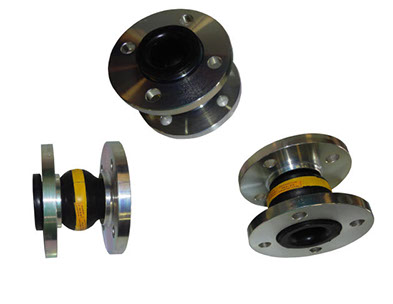

Expansion Joint - Navy

Spool type expansion pipe and used in single or multi arch types.

Connects to concentric or eccentric tapers and unequal diameters.

Seamless flange face eliminates a need for gaskets.

High pressure and vacuum resistant for increased safety applications.

Can be custom designed for greater movement capability and easier installation.

Variety of elastomer and fabric combinations for temperature, pressure and media.

Liners: hypalon, EPDM, nitrile, neoprene, and natural.

Expansion Joint - Navy

Spool type expansion pipe and used in single or multi arch types.

Connects to concentric or eccentric tapers and unequal diameters.

Seamless flange face eliminates a need for gaskets.

High pressure and vacuum resistant for increased safety applications.

Can be custom designed for greater movement capability and easier installation.

Variety of elastomer and fabric combinations for temperature, pressure and media.

Liners: hypalon, EPDM, nitrile, neoprene, and natural.

High Pressure Fittings

2,000, 3,000, 6,000 10,000 PSI

Forged fittings to ASME B16.11 and ASME B1.20.1.

Carbon steel, S/S 316L, nickel alloys, chrome molly, aluminium, CuNi and titanium.

Tees, crosses, elbows, laterals, plugs, couplings, reducers, caps and unions.

Mercury / chloride / halogen / zinc and silicon free.

Markings: Heat code traceability and PSI range.

Ultra high pressure fittings to 150,000 PSI.

Adaptors, couplings and pressure gauges supplied.

Spacer Flexible Pipeline Rubber

Yellow band expansion joints designed for petroleum based products, fuel ethanol blends.

Town and natural gas applications except LPG

Liner: NBR (nitrile).

Flanges: DIN PN 10/16.

Electrically conductive.

Temperatures: -20°C to +90°C

Sizes: 25 DN to 1000 DN @ 10-16 bar.

Pressure Damper Stainless Steel or Brass

Stainless steel, 400bar, gas.

Brass: 200bar or steel: 600bar.

Dissipates pressure waves.

Lateral setting spindle.

Connections G1/2.

Explosive group: 11A, 11B and 11C.

Parameters: AF 27mm x 60mm (L) x 300g.

Gasket Spiral Wound - Navy

Manufactured IAW MIL-G-24716 Type II Class ‘A’.

Spiral wound gasket for flat and raised face flanges, prevents gasket blow out.

Utilises external ring, which accurately centres gasket on flange face.

Provides resistance to virtually every known corrosive and toxic element.

Uses: precision engineered joints, heat exchanger and boilers etc.

Applicable Standards: ASME B16.20/BS3381.

Maximum temperatures up to 1800ºF / Minimum temperatures down to -400ºF.

Silbraze Rods

A56T – Bag - 7

Cadmium free, high silver alloy.

Maximises flow and has excellent wetting characteristics.

Minimises brazing temperatures.

Melting Range: 1145°F to 1205°F.

Material safety data sheet available on request.

Sizes Available: 1.6mm and 2.5mm diameter.

Product Uses: welding, brazing and soldering.

Silbraze Rings – 56%

Silver

Insert ring 56% silver Bag 7.

Manufactured to MIL-J-1183J.

Sizes: ½” to 8” in diameter.

Cadmium free – in single or multiple turns, rings, washers, discs and flat.

Material safety data sheet supplied.

Note: silver prices are per LME.

Letter of conformance supplied.

Wrought Copper and Bronze

Banninger 5000 Range – Solder Fitting in Copper

Size 8mm to 76mm.

Bends 180, 90, 45, Crossovers, Part Crossovers, Tees, Reducers and Adaptors.

Unions, Union Elbows, Adaptors, Pitcher, Tees, Caps, and Couplings.

Resistant to corrosion and harsh weather conditions.

Uses: gas, water, sanitary, heating and general engineering.

Metric and imperial sizes available.

Pipe Emergency Repair Kit - Navy

NSN 4730-00-542-3359

Ship damage control repair kit 1.

Conforms to Mil-R-17882.

For metallic pipe and general purpose damage control.

Contains: liquid resin,

liquid hardener,

woven glass cloth,

void cover,

PVC film,

paint paddle,

chalk line,

abrasive cloth,

scissors,

polyerhylene gloves and

spectacles.

Pipe Repair Kit - Navy

NSN: 4730-00-542-3362

Pipe kit, emergency repair and damage control.

Used for providing emergency repairs on low / medium pressure systems.

Goods to be stowed together as a kit for immediate access.

Specification: conforms to Mil-R-17882.

Hazard identification documentation.

Fire fighting, handling, storage and first aid procedures supplied.

SERVICES & CAPABILITIES

ENQUIRIES

If you would like more details on a particular product or service please fill out and submit the form below and one of our team will contact you with more information.

PAGE LINKS

All Rights Reserved © 2018 | Bale Defence Engineering Systems Pty Ltd