Shipboard Equipment

Home / Products / Shipboard Equipment / Shipboard Equipment Supply / Strainers

Strainers

Sediment Strainer

Cast bronze – sizes: 1/4" to 3".

Used to strain foreign matter from pipelines and provide pump protection.

Conforms to BuShip Drawing 810-841499.

Construction – straight threaded.

Self-cleaning by opening plug on 'Y' section.

Rating: up to 400psi @ -20 to 100ºF.

Y Strainer - Sediment, Flanged

"Y" Strainer - Sediment, Flanged

Available in steel, stainless steel, CuNi 70/30, CuNi 90/10 or aluminium.

Used to strain foreign matter from pipelines.

Economical protection for pumps, meters, valves and other mechanical equipment.

Flanged, socket weld, sil-braze ends or buttweld.

Strainers to MIL-S-13789A and MIL-B-24480.

MIL-S-002953C: Class A, B & D.

Navships #810-8441499.

Navy ‘Y’ Strainers

Sizes 1/4" to 12" (6mm to 300mm).

Flanged, threaded, socket, silbraze / sweat, solder.

Military, DIN / JIS or VG specification.

Bronze, steel, iron or stainless steel.

Used where infrequent cleaning is required.

Baskets: bronze, stainless steel and monel.

Capacity: 125lb to 600lb.

Flanged "Y" Strainer Bronze

Cast Bronze, flanged end "Y" strainer.

Sizes: 1/2" to 12".

Used to strain foreign matter from pipelines and provide economical protection.

rating ( model 851M): 225 psi @ -20°F to 150°F.

Self cleaning via blow off outlet.

Screens 304 stainless steel with various perforations.

Generously proportioned bodies.

Navy ‘Y’ Strainer

Flanged nickel aluminium bronze ‘Y’ strainers.

Sizes: 1/2" to 12".

Flanges drilled to ASME B16.24.

Screen sizes 1/16" to 1/8" in 304 stainless steel.

Can be installed in downward and horizontal lines.

Piloted body and cover for proper alignment.

Typical order above BA-7-150-4.

Navy 'Y' Strainer, Steel - Series 600PSI

Sizes: 1/4 inch to 2 inch.

Cast steel body, stainless steel basket.

Ends socket weld to ANSI B16.11.

Shock Grade 'A' as per Mil-S-901D.

Shock test extension as per Mil-Std-798.

OQE, COC, WCCS supplied.

Basket perforations: 1mm - stainless steel.

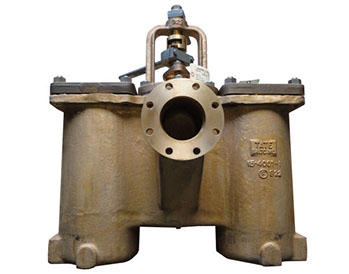

Strainer Double 150lb Flanged

Uses: naval, water, fuel, utilities, chemical and process equipment.

Retains contaminants that will be harmful down stream.

Reduced life cycle costings.

Materials: bronze, stainless steel, cast steel and alloy 20.

Strainer media: perforation sizes from 1/32" to 1/2".

Manufactured in accordance with ASME specifications.

Sizes: 1/2" to 8".

Navy Hellan Strainer, Double, 150lb

Inline flow body dual screen strainer.

Sizes: 2-1/2", 3", 4", 6", 10" & 12" models.

Employs 2 handwheel equipped rotating screens.

Rigid scraper bar removes solids from screen surface.

Solids collectable sump is provided.

Cleaning cycle performed when strainer is under positive pressure.

Installed in the vertical up flow position or on the horizontal.

Strainer Simplex 150lb

Sizes: 1-1/2" to 8".

Threaded or flanged ends.

Single basket strainers available in cast bronze, cast steel or stainless steel.

Top entry basket, quick opening and positive sealing.

Easy removal and cleaning of basket.

Typical application: removal of debris for start up or emergency protection.

Duplex Strainer

Sizes: 1/2" to 8".

Body materials: cast steel, bronze, stainless steel and alloy 20.

Maximum working pressure: 150lb and 250 PSIG.

Inlet / outlet connection: flanged.

Access cover type: quick opening yoke or bolted.

Basket fluid entry: top.

Used where heavy duty straining is required in continuous operations.

Navy Strainer Baskets

Sizes 1/4" up to 8” in size.

Materials: 316 stainless steel, monel or CuNi.

Wide range of perforations and mesh size.

Suitable for simplex or duplex strainers.

Heavy duty, pleated and slant top models available.

Bow shaped handle ensures tight seal.

Magnetic inserts available for microscopic iron particles.

SERVICES & CAPABILITIES

ENQUIRIES

If you would like more details on a particular product or service please fill out and submit the form below and one of our team will contact you with more information.

PAGE LINKS

All Rights Reserved © 2018 | Bale Defence Engineering Systems Pty Ltd